Tips for solder flow

Moderators: pompeiisneaks, Colossal

Tips for solder flow

I'm starting to solder a populated board with double turrets (chrome) from AES and I'm having an uncharacteristically hard time getting the solder to flow. I'm getting solder balls on components and turrets that are HOT AS. I brushed on some solder flux and it helped on the wires, but the turrets still don't want to run with it. Naptha?

Just plug it in, man.

Re: Tips for solder flow

What a nightmare!

At a guess, an oxide surface layer may have formed.

A fine abrasive brush may be your best bet for turrets. Not metal bristles that shed though

I suppose they’re a popular retailer over in North America, but from a few ‘bad experience’ comments, I get the impression that their product standards could be improved?

At a guess, an oxide surface layer may have formed.

A fine abrasive brush may be your best bet for turrets. Not metal bristles that shed though

I suppose they’re a popular retailer over in North America, but from a few ‘bad experience’ comments, I get the impression that their product standards could be improved?

My band:- http://www.youtube.com/user/RedwingBand

Re: Tips for solder flow

Have you tried a contact cleaner? It seems the turret has oxides on its external layer.

- Colossal

- Posts: 5050

- Joined: Sat Oct 20, 2007 9:04 pm

- Location: Moving through Kashmir

1 others liked this

Re: Tips for solder flow

I agree with Pete; this is bad QA/QC. This issue with cheap import turrets not taking solder has come up before. The lesson here is buy US made turrets. Keystone Electronics.

Personally, I would return the board and turrets and get a refund and tell them you expect better.

Personally, I would return the board and turrets and get a refund and tell them you expect better.

Re: Tips for solder flow

I'll try a bit of Deoxit and hope for the best. Thanks, Colossal, for the Keystone referral.

Just plug it in, man.

Re: Tips for solder flow

Yes, I have struggled with this before. Try a brass-bristled brush before applying flux.

I build and repair tube amps. http://amps.monkeymatic.com

Re: Tips for solder flow

Just out of curiosity, and I understand saving money on turrets that don't wick solder ain't worth the toilet paper, but do you like $0.33 per turret for Keystone hollow double turrets?

Just plug it in, man.

Re: Tips for solder flow

Buy turrets from Hoffman. $0.17 and no regrets...

https://hoffmanamps.com/MyStore/perlsho ... =!ORDERID!

Re: Tips for solder flow

I use Keystone as well.

Cheers

G

Cheers

G

Re: Tips for solder flow

Some of the Asian prefab turret boards have weird plating, and regular lead-based solder doesn't seem to stick to them very well. I guess try wire brushing them?

-

thetragichero

- Posts: 476

- Joined: Tue Sep 10, 2019 7:46 pm

Re: Tips for solder flow

this goes against the suggestion for something that doesn't shed metal, but i picked up some small 5x5 turret boards from the electronic surplus store that were probably sitting there for years. i used #0000 steel wool on the turrets and then wiped everything with a cotton rag soaked in denatured alcohol. solder flows considerably better than before, but one must be careful with the steel "hairs" (a compressor to blow off the excess is also a good idea, but i used these for low voltage fuzz pedal builds so a good wipe down was sufficient for me)

PRR wrote: Plotting loadlines is only for the truly desperate, or terminally bored.

- statorvane

- Posts: 557

- Joined: Thu May 11, 2006 3:28 pm

- Location: Upstate New York

Re: Tips for solder flow

Here's a simple approach that worked for me a while back. Not turrets but eyelets. Same problem - would not take solder. I etched them overnight in vinegar (acetic acid). The next day they worked fine.

Re: Tips for solder flow

Thanks all for the great ideas. I mean, this board is fully-loaded, so I'm going to try to triage the board. I sprayed all the turrets with Deoxit. The few turrets I tried showed some improvement, but I like the acid idea. I might try that. I've never had solder balls build up on a turret sidewall. Good gosh.

Just plug it in, man.

Re: Tips for solder flow

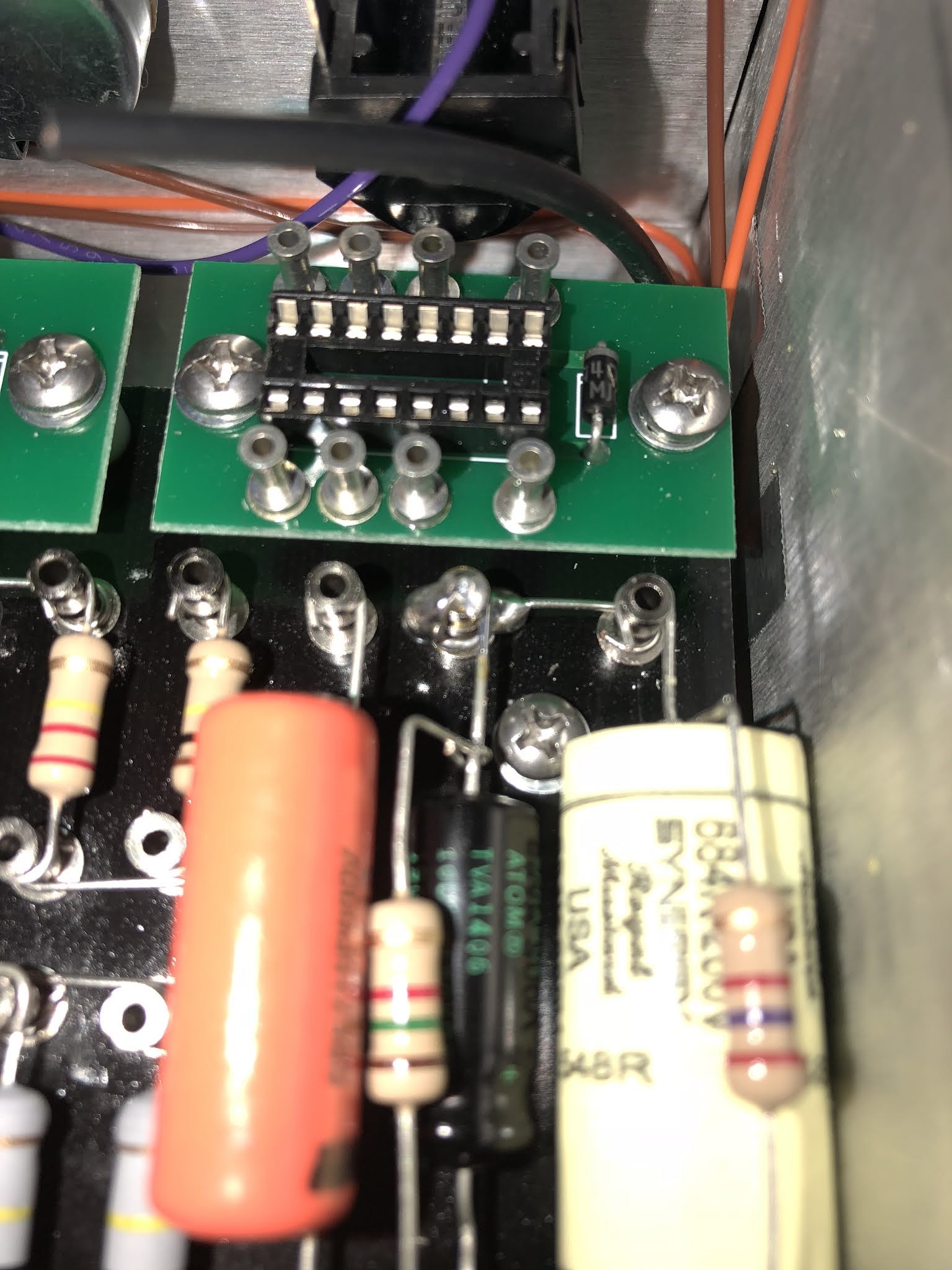

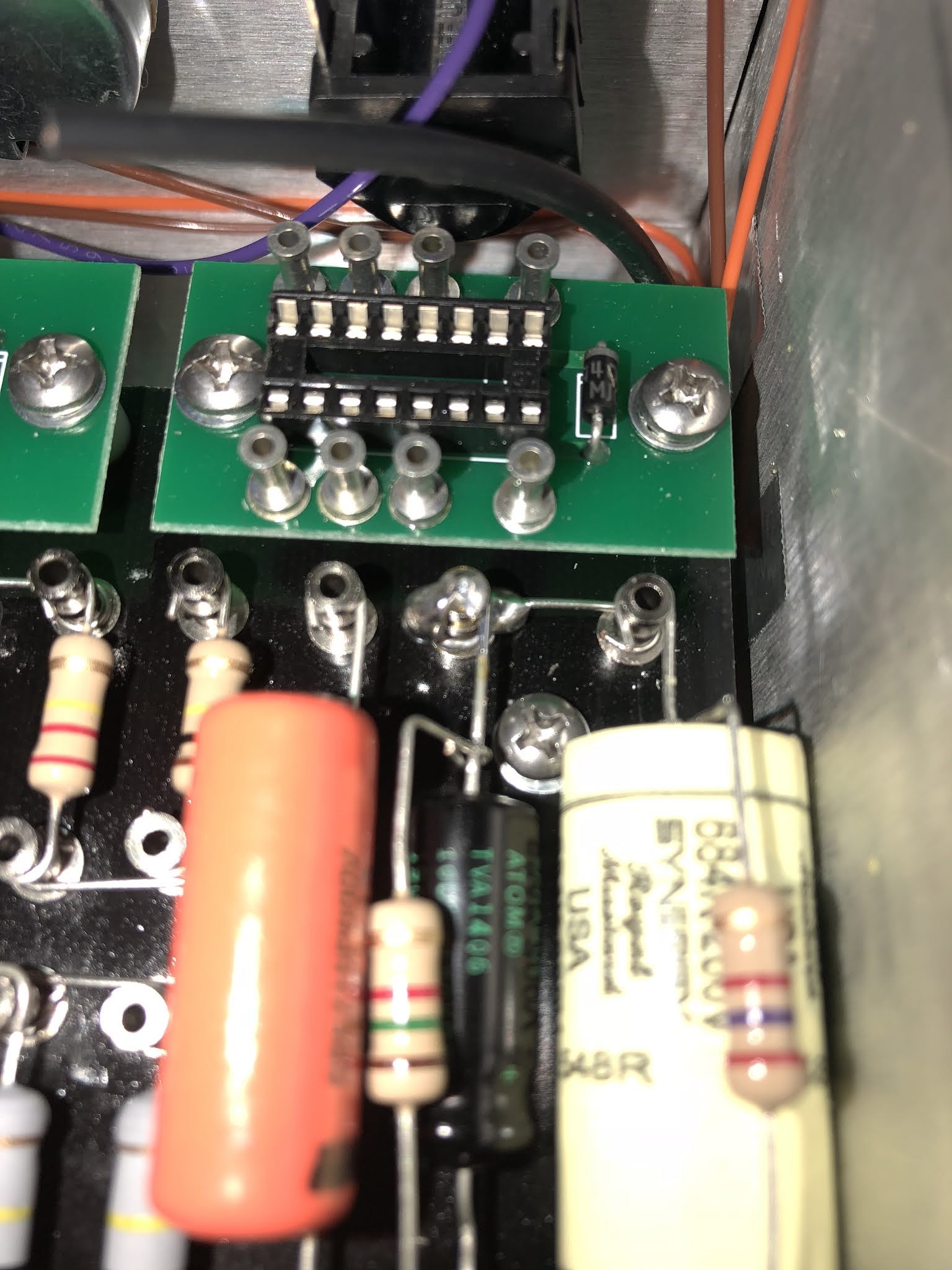

So I’m a fairly reasonable guy, but seriously, have you ever seen solder do this??? See the turret above the black cathode cap.

None of it is on the board. I apologize for the focus, but it’s shiny...and levitating.

None of it is on the board. I apologize for the focus, but it’s shiny...and levitating.

Just plug it in, man.

Re: Tips for solder flow

Man that sucks, and yes I’ve had that happen with turrets I bought at AES. Before. I have about 150 of them waiting for 2 amp builds.

I’ll be extremely peeved if these are like yours...

I think I’ll try a few solder tests before I populate a board.... thanks for all the tips.

Good luck Viper, hope it works out for you

I’ll be extremely peeved if these are like yours...

I think I’ll try a few solder tests before I populate a board.... thanks for all the tips.

Good luck Viper, hope it works out for you