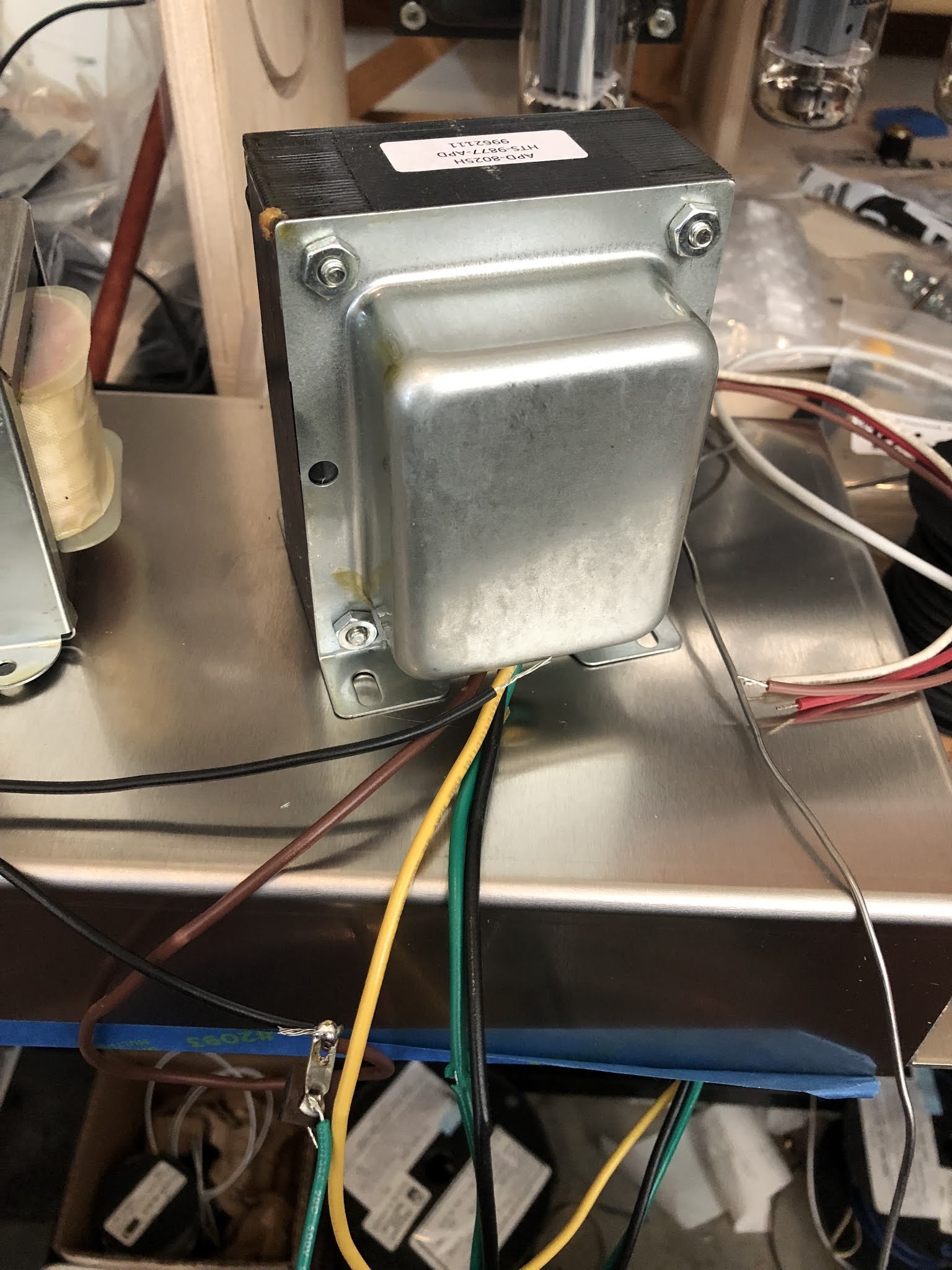

Send it back is the best and first option as other have said. IMO, the seller is responsible for packing to avoid shipping damage. It looks like a serious shipping bruise because it was floating inside the box. Really, it just takes a bit of wadded up brown paper or foam sheet goods to do a decent packing job.

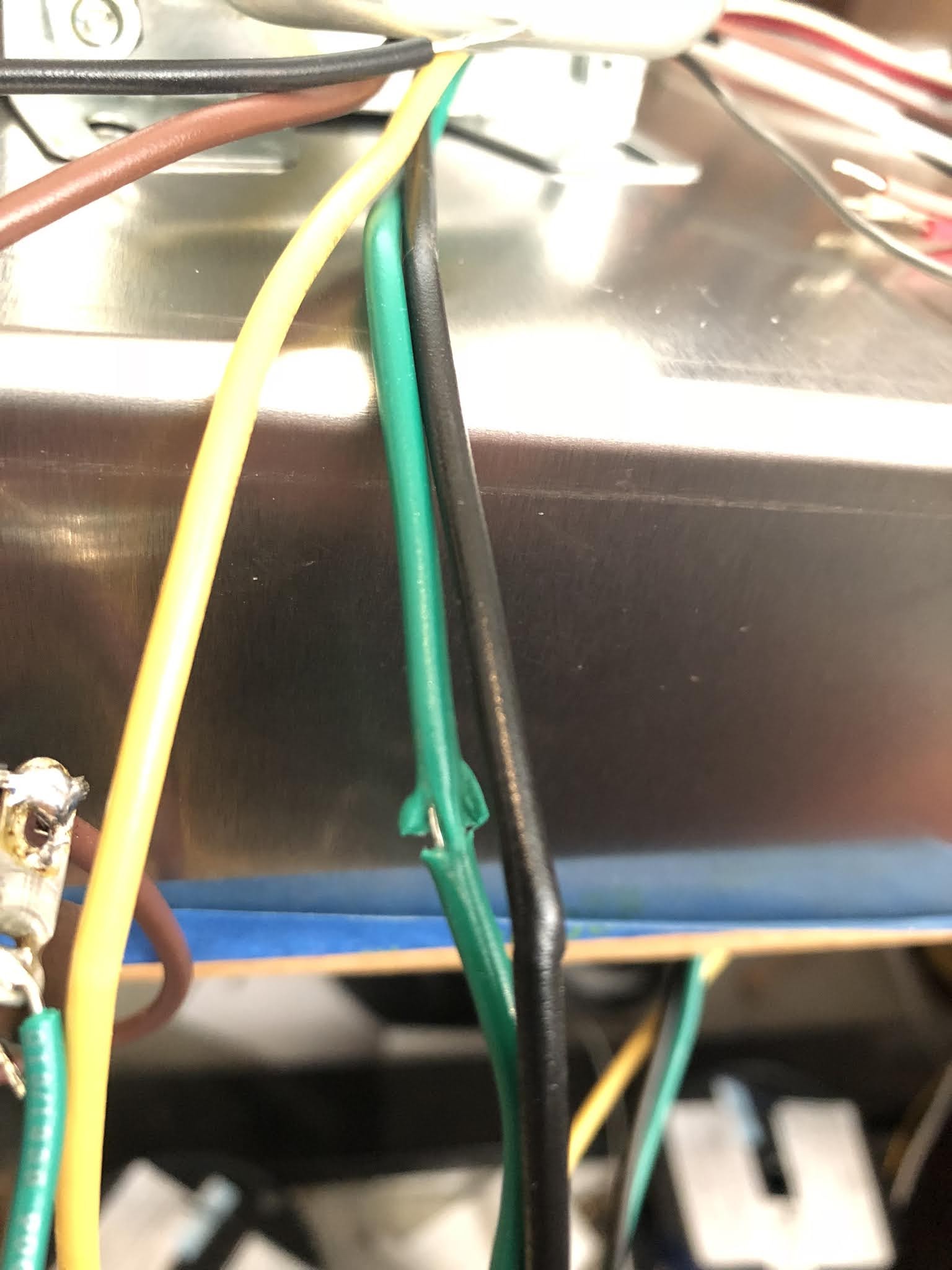

If a replacement isn't going to happen, then a repair is certainly possible. I can't really tell from the pictures if the problem is just the insulation getting messed up or if the stranded wire is also broken. If it is just the insulation, I would probably trim the insulation humps (use a razor blade, side cutters, or small scissors) without nicking the actual wire, and cover with heat shrink. Maybe I'd use two layers of heat shrink if I thought it was a bit too thin. If some of the wire is broken, you really should clip, splice, and cover with heat shrink. I've done this. It's not a big deal.

FWIW, I have found the Western Union splice (the gold standard) to be too bulky and stiff after soldering. I don't believe the WU splice was meant to be soldered and I'm not comfortable just covering with heat shrink. Instead, I will twist and solder. Twist can be done with shorter wire length than a WU splice. Then cover with heat shrink. This will leave it uncovered at the base. The solution is to bend it next to the insulated lead and then heat shrink again so the splice is parallel to the lead. I hope that is clear. Then again, maybe you can do a better WU splice than I can or you are willing to forgo the solder.

There is always the NASA splice:

https://www.youtube.com/watch?v=O-ymw7d ... 1g9XgCoAEC

Good luck.